Service

Flow Synthesis /

Halogenation StudiesContract research and

development

Comprehensive support in flow synthesis and process development

using cutting-edge flow synthesis and monitoring technologies.

Service contents

Contracted Research Services in Flow Synthesis

Advanced reaction control and quality management based on real-time monitoring technology can address all challenges of organic chemistry.

Contracted Research Services in Halogenation Studies

Drawing on our experience with hazardous materials, including Cl2 gas, liquid Br2, HCl gas, HBr solution, and fluorine gas, we address challenges in halogenation.

For the diverse needs in compound synthesis,

Syncrest's technology provides the solution.

Contract research of flow synthesis

Why don't you realize that reaction that

you had given up with

Syncrest's cutting-edge flow synthesis?

What is the flow synthesis method?

The flow synthesis method is a new chemical synthesis method in which a thin tube is used as a reaction field, and a chemical reagent as a raw material is continuously mixed and reacted while flowing into a tube to obtain a target substance.

Compared with the batch synthesis method used extensively in industrial manufacturing (a method in which chemical reagents are mixed and reacted in a reaction kettle), the production volume can be adjusted in a flexible manner, and a high-risk reaction that is difficult to perform in a reaction kettle is also possible, so that the scope of application and scale flexibility of the chemical reaction will be greatly expanded.

In addition, since the reaction is carried out in a thin tube, the energy required for temperature and pressure adjustment and agitation can be suppressed, and this is attracting attention as an energy-saving and sustainable synthesis method.

Features of Syncrest's

flow synthesis

Syncrest's flow synthesis method integrated with in-line measurement, which combines flow synthesis technology and sensing technology, enables continuous production using a unique system that integrates everything from compound synthesis to purification.

Precise reaction control supported by non-invasive in-line sensing technology solves process problems, suppresses side reactions, and achieves high yield and purity.

Contract research on flow synthesis

Syncrest's state-of-the-art flow synthesis and monitoring technology solves a variety of batch synthesis problems.

From solving problems such as yield improvement and purity improvement in general, to dangerous reactions that are difficult to perform in batches, high-temperature/low-temperature reactions, and reactions that are difficult to scale up, please contact us.

Flow-Synthetic experts consistently and fastest respond to g~kg manufacturing and refining from reaction conditioning to the construction of systems optimized for your reaction system, including liquid delivery testing and monitoring.

- Review of

reaction conditions - Construction of

systems - Trial operation,

liquid feeding test - Manufacturing

(g-several tens of kg) - Refining

Examples

- Hazardous reactions (cyanation reactions using KCN, etc., reactions using high-pressure ammonia gas, bromination/iodination reactions using HX)

- Reduction (H2 reduction)

- Halogenation (bromination with liquid Br2, chlorination with Cl2 gas)

- Synthesis and Reaction of Organometallic Compounds (Synthesis of Grignard Reagents and Apply to Grignard Reactions)

| Temperature | Pressure | Production Volume | Immobilized Catalysts | Types of Gases | Other reagents | |

|---|---|---|---|---|---|---|

| Application Range |

-78 ℃ ~ 260 ℃ |

Atmospheric Pressure ~ 15 Mpa |

10 mg ~ 200 kg |

Pd, Ru, Rh, Zn, Cu, Mg |

(F2), Cl2, H2, NH3, Me2NH, (HF), HCl |

nBuLi, MeSH, N2H4, Br2, BBr3 |

-

Automatic cleaning and multi-product automatic manufacturing using switching valves

-

Fluid Br2 for bromination

Contract research of halogenation

We will contribute to

solving halogen-related issues

by utilizing halogenation technique that

we have cultivated over many years.

Characteristics of Syncrest's

halogenation technique

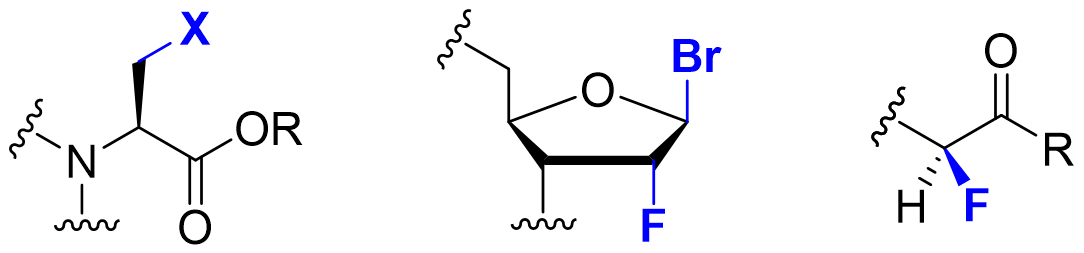

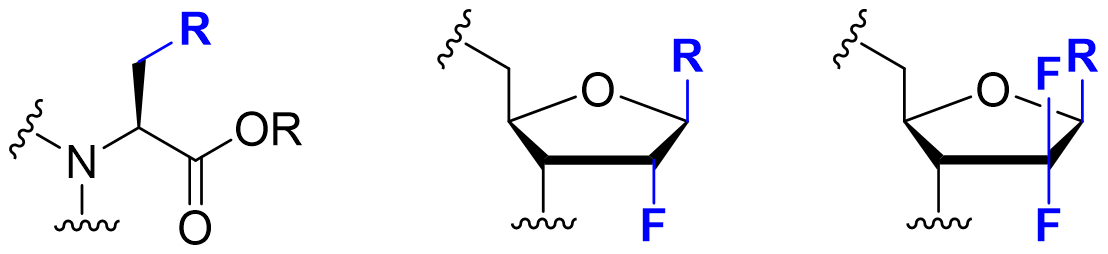

Syncrest has inherited halogen-related technologies on an industrial scale that Otsuka Chemical has cultivated for more than 60 years. We are also developing original organic synthesis and purification techniques by making the most of our halogenation technology and handling know-how. In addition to dealing with general-purpose halogenating agents (Cl2 gases, liquid Br2, Hcl gases, HBr solutions, etc.), we are also working to develop a variety of new halogenations through collaborative studies. We are particularly good at fluorinating the carbonyl group at the b-position.

Example of manufacturing

Halogen-containing raw materials for the synthesis of middle-molecular drugs and low-molecular compounds

Raw materials for the synthesis of middle-molecular drugs and low-molecular compounds via halogen intermediates

Contract research of halogenation

Halogen-handling experts reduce the route of halogenation reactions and consider the handling of hazardous reagents and their combination with flow synthesis. In this way, we construct a reaction system that is optimized for your request and respond consistently and at the highest speed.

- Examination of

reaction routes - Construction of

reaction systems - Small-scale

prototyping - Production

(g-several tens of kg)

-

Chlorination reaction using chlorine

-

Ensuring safety by developing in-house equipment