Technology

Flow Synthesis Technology

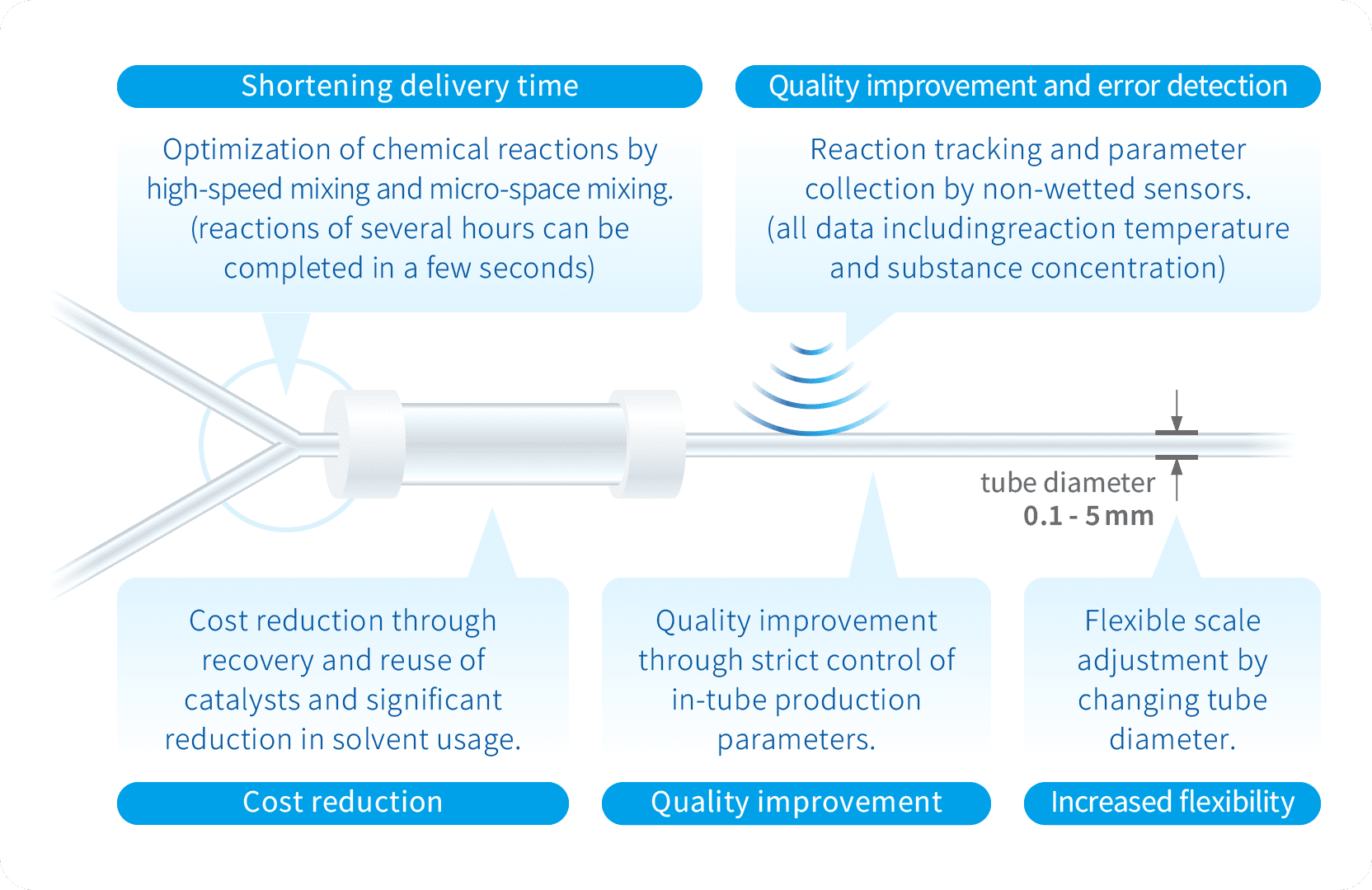

Continuous production by the flow synthesis method*1, which draws the line with the previous batch reaction method*2, allows flexible adjustment of the production volume by extending the liquid feed time. In addition, since the reaction is carried out in a closed system, it is possible to deal with hazardous reactions and other chemical reactions that cannot normally be realized in a reactor.

Syncrest has a unique flow synthesizer that allows you to perform the synthesis and purification of compounds in an integrated, gas-tight fashion.

We have built a high-quality, inexpensive, and on-demand synthesis and manufacturing system that ensures precision, robustness, and high quality by comprehensively utilizing high-speed mixing and micro-space mixing to speed up reactions, efficient conversion of compounds using our unique catalyst technology, and advanced reaction control using various sensors.

*1 Flow synthesis method:

It refers to a method in which a thin tube is continuously charged from one end of a tube, a raw material is continuously charged from one end of a tube, and a product is continuously obtained from the other end.

The flow synthesis method is said to have higher energy efficiency and less waste emissions than the batch synthesis method.

*2 Batch reaction method:

It refers to a method in which all raw materials are charged into a reaction kettle, and after all of the reaction is completed, a product is taken out.

Sensing Technology

By combining and inheriting Otsuka Chemical's cutting-edge flow synthesis technology, medium-molecular drug manufacturing technology, and GMP control know-how with Yokogawa's world-leading measurement and control technology, we have succeeded in developing the world's most advanced continuous flow synthesis method integrated with in-line measurement*3 that enables non-destructive, high-precision measurement of objects to be measured in real time.

The continuous flow synthesis method integrated with in-line measurement provides comprehensive and thorough monitoring of the entire process from synthesis to purification of compounds using non-invasive sensing technology, enabling real-time reaction tracking, parameter collection (all data on reaction temperature, substance concentration, etc.), and immediate corrective control when abnormalities are detected.

We will contribute to the improvement of productivity by consistently responding to the needs of pharmaceutical companies focusing on middle-molecular drugs, from basic drug discovery research to process development. We will respond to various issues and needs related to Q (quality), D (delivery), and C (cost) in the value chain for manufacturing pharmaceuticals that can be synthesized in various ways, mainly for middle-molecular drugs, and provide the necessary quantity, when necessary, with the highest quality.

*3 Continuous-flow synthesis method integrated with In-line measurement :

It refers to a flow synthesis method that realizes process continuity by integrated control through in-line measurement in multiple production processes from reaction to purification and extraction.

Continuous production of

a series of processes

from synthesis to crystallization

In December 2022, the Naruto Factory (in Otsuka Chemical's Naruto Factory) was completed as

a multi-purpose plant for manufacturing APIs, intermediates, and raw materials for middle-molecular drugs.

This plant will be the first multi-purpose, multi-product plant in Japan to meet GMP of

high pharmacological activity (OEB category4*4)

that can be produced using a continuous-flow synthesis method.

It is also equipped with a Non-GMP area. This allows for a diverse and flexible manufacturing system.

In addition, we have solid-phase synthesis equipment, state-of-the-art equipment,

and various analytical equipment, which enable high-purity on-demand production of APIs,

API intermediates, and raw materials capable of performing various chemical syntheses,

mainly of middle-molecular related,

as well as middle-molecular drugs.

*4 OEB(Operational Exposure Band):

Occupational exposure bands. Acceptable exposure control category for drug substance.